Solutions for gas analysis in cement plants

CEMTEC® – For extreme conditions

The CEMTEC® gas sampling system has been developed for continuous flue gas analysis in cement kiln inlet chambers and in other extremely dusty high-temperature processes. Increasing the efficiency of pyro processes and ecological sustainability are global requirements and an be implemented with CEMTEC®.

CEMTEC‘s® superior design accommodates the increased trend to use alternative fuels.

These advantages have been confirmed by Enotec's customers:

- Decreased ammonia consumption due to improved SNCR efficiency

- Reduced fuel consumption due to higher combustion efficiency in the rotary kiln and in the calciner

- Lower emissions due to reduced fuel consumption and continuous emissions monitoring

- Higher refractory lining durability due to lower CO emissions

- Lower maintenance of the cyclones and riser duct due to reduced material build-up

- 95% availability of measurement data enables continuous process control and monitoring

Our promise:

We will find a solution for your application, whether customized or from mass production.

Enotec's wide range of products and Westech's ability to execute custom-made projects, directly in-house, enables us to find the right solution for every application. Long-lasting and to the highest satisfaction of our customers.

The process of cement production is characterized mainly by the extreme conditions:

Extremely high temperatures and high dust loads.

In order to operate the process efficiently and with a minimum of emissions, quick and reliable measurements are essential.

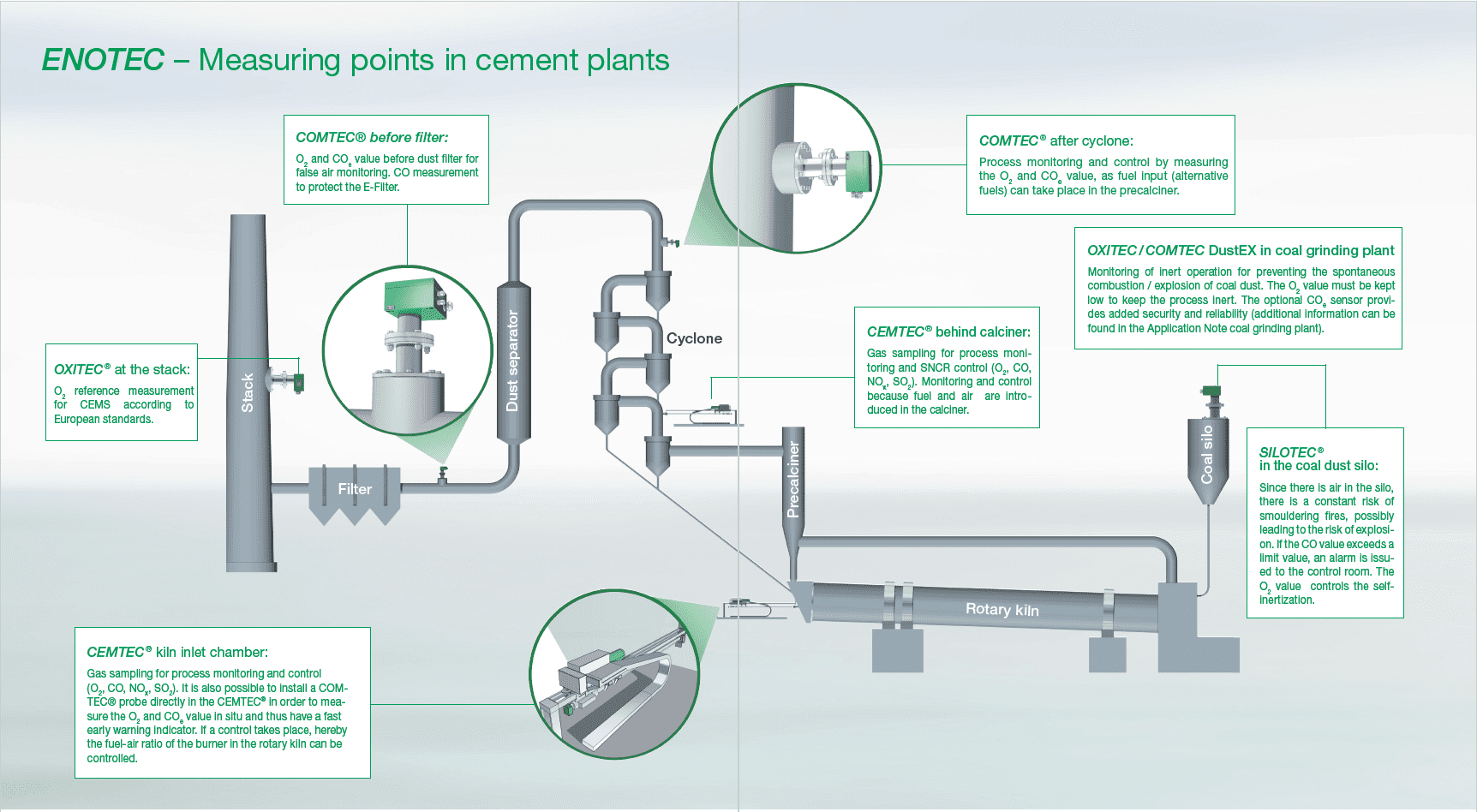

Especially the measurement in the kiln inlet chamber at the end of the rotary kiln is important since the excess O2 content in the flue gas can be measured as close as possible behind the burner (approx. 2,000 g / m3 dust).

The water-cooled sampling probe CEMTEC® is used here, with 95% availability, sample gas is constantly extracted from the pyrolysis process from the rotary kiln.

Downstream of the precalciner, at somewhat lower temperatures but with similarly high dust loads with higher flue gas velocity, CEMTEC® is used for measurement.

For the measuring points for thermal fuel preparation,flue gas cleaning and at the chimney, OXITEC® 5000 (O2 InSitu measurement) and COMTEC® 6000 (O2 / COe in situ measurement), are used in order to obtain reliable and fast measurements for process control and monitoring.

Process stages in the cement plant:

- Rotary kiln: clinker formation (sintering)

- Precalciner: completion of calcination

- Cyclone: drying, preheating and a limited calcination of the raw meal