Case Study: Heat and Electricity for All of Kuopio – Verifiably Lower Emissions with SICK Sensor Intelligence

We are thrilled to present a remarkable case study that showcases the power of SICK Sensor Intelligence in revolutionizing emissions monitoring and energy production. Discover how Kuopion Energia, a leading energy company in Finland, leveraged our MCS200HW multi-component analyzer system to achieve unparalleled efficiency, lower emissions, and reliable supply of heat and electricity to the city of Kuopio.

The Challenge: Modernizing for Cleaner Production

As a responsible energy provider, Kuopion Energia understood the importance of continuously modernizing its power plant to comply with emissions laws and reduce its environmental impact. With the need for a versatile and low-maintenance analyzer system, the company turned to SICK for an innovative solution.

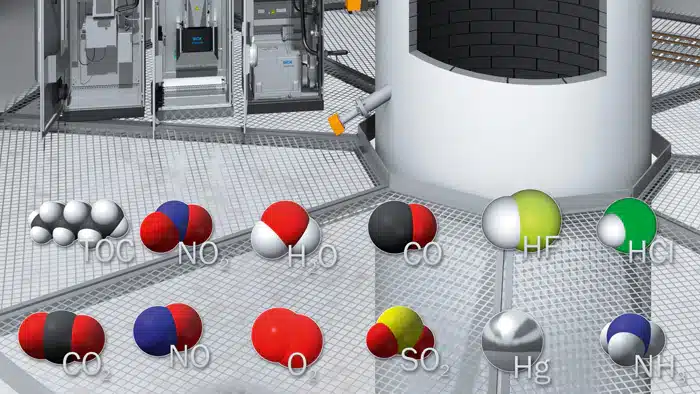

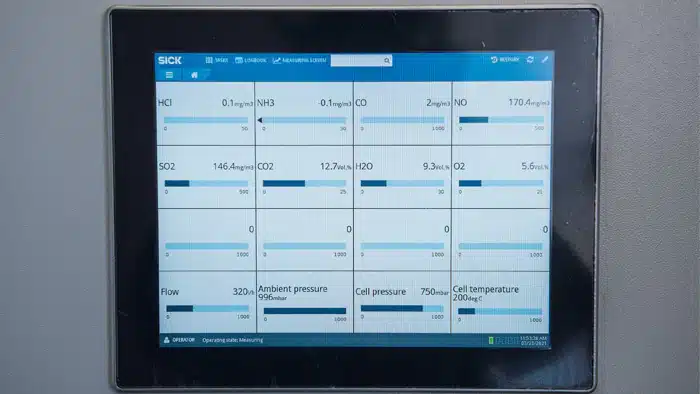

The Solution: MCS200HW Multi-Component Analyzer System

Kuopion Energia implemented the MCS200HW multi-component analyzer system, which replaced the outdated testing system in the stack. This cutting-edge analyzer system offered advanced sampling capabilities, enhanced versatility, and low-maintenance operation, enabling precise monitoring of emissions while ensuring the reliable supply of heat and electricity to the city.

Optimizing Efficiency and Lowering Emissions

Through the integration of the MCS200HW system, Kuopion Energia achieved remarkable results. The power plant experienced significant fuel savings of 200-250 GWh annually, representing approximately 15% of the plant's total fuel consumption. This optimization was made possible by utilizing the energy generated from a flue gas scrubber and a district heating accumulator, providing flexibility in electricity and heat production.

Reliability and Ease of Use

The SICK MCS200HW analyzer system proved to be an easy and reliable solution for Kuopion Energia. With its sampling probe and maintenance-free ejector, the system ensured smooth and uninterrupted operation. The analyzer system's design, including the heating of the gas transfer path, prevented condensation, washed-away gas components, and corrosion, ensuring accurate and reliable measurements.

Unleashing the Potential of SICK Sensor Intelligence

The MCS200HW multi-component analyzer system from SICK offers unmatched versatility and upgradeability. With its ability to simultaneously measure up to ten gas components and provide automatic quality assurance, the system can be tailored to meet specific requirements. The result is an economical and reliable solution that empowers energy providers to monitor emissions effectively, optimize energy production, and reduce environmental impact.

Experience the Future of Emissions Monitoring

Are you ready to take your emissions monitoring and energy production to new heights? Discover the power of SICK Sensor Intelligence and explore the full potential of our MCS200HW multi-component analyzer system. Contact our experts today at [contact information] to learn more and embark on a journey towards a cleaner, more sustainable future.

Read the full case study here and witness how SICK Sensor Intelligence transformed the energy landscape in Kuopio, Finland.

Together, let's shape a greener tomorrow with SICK Sensor Intelligence.